Add to Cart

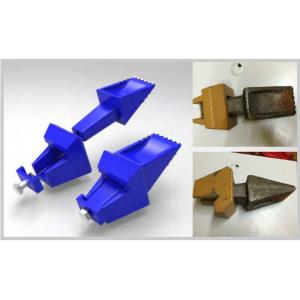

Drilling Bucket Soil Teeth Construction Auger Teeth Drilling Bucket Flat Teeth

Product Feature:

1.drilling bullet bits, Flat Teeth and roller bits use high grade alloy steel and tungsten carbide tip and adopt advanced brazing technology to produce high quality, high wear resistance, long life cutters. we also can produce all kind of rotary bits, trenching bit and flat bit according to customers' requirements.

2.Drilling rig's cutting tooth including soil teeth, bullet teeth and roller bits. Soil teeth mainly include:V20, FZ80, 22S etc. Bullet teeth include DF 3050, DF 3050LH, DF 3050A, DF 3050AQ etc. Roller bits include weld type, replaceable type and so on.

| Technical Specification of Flat teeth(soil teeth) | |

| Product name | Soil Teeth |

| Material | High alloy steel+special elment |

| Usage | Foundation construction |

| Process | Forging |

| Color |

As per customer's requirments |

| Certification |

ISO9001 |

| Technology | Casting |

| Application | Rotary drill rig |

| Model | Weight(g) |

| V20 | 5307 |

| 22S | 3873 |

| FZ80 | 9871 |

Product Details

FAQ

Q1: Are you a trading company or a manufacturer?

A1: We are a professional manufacturer, and our factory mainly produces hydraulic pilling rig, hydraulic pile breaker, telescopic arm and related piling equipment etc. Our products have been exported to more than 50 countries of Asia, South America, Africa,and have developed a good world wide reputation.

Q2:What kind of product certification do you have?

A2: All our products have passed ISO9001 and CE certifications and also passed the inspection by the Chinese National Construction Machinery Quality Inspection Center. We have strict quality inspection process including a load test for every machine before leaving our factory in order to offer the best quality machines to our customers

Q3: Do you have after sales service?

A3:Yes, we have special service team which will offer you professional guidance. If need be, we can dispatch our engineer to your worksite to provide training for your staff. For the chassis, e.g CAT chassis, we take advantage of their global presence to ensure prompt after service support. During the epidemic, we provided video for machine installation and operations.

Q4:How about the warranty policy ?

A4:We offer one-year warranty or 2000 hours of operations, whichever comes first, for our products.

Q5:Do you test all your goods before delivery?

A5 :Yes, we have strict quality inspection process including a load test for every machine before leaving our factory.